Matsalolin Fiber na Gilashi

1.Tabarmar Zaren da Aka Yanka (CSM)Gilashin fiber roving(wani lokacin kuma ana ci gaba da juyawa) ana yanke shi zuwa tsayin mm 50, bazuwar amma daidai gwargwado akan bel ɗin raga na jigilar kaya. Sannan a shafa maƙallin emulsion, ko kuma a shafa maƙallin foda a kai, sannan a dumama kayan kuma a warke don samar da tabarmar zare da aka yanka. Ana amfani da CSM galibi a cikin shimfida hannu, yin panel akai-akai, gyaran ma'aunin mutu, da kuma tsarin SMC (Sheet Molding Compound). Bukatun inganci na CSM sun haɗa da:

- Nauyin yanki iri ɗaya a faɗin faɗin.

- Rarraba zare iri ɗaya a saman tabarmar ba tare da manyan ramuka ba, da kuma rarrabawar manne iri ɗaya.

- Ƙarfin busasshen tabarmar matsakaici.

- Kyakkyawan kayan aikin jika da shigar azzakari.

2.Tabarmar Filament Mai Ci Gaba (CFM)Ana sanya zare-zaren fiber na gilashi masu ci gaba da aka samar yayin aikin zane ko kuma a cire su daga fakitin roving a cikin tsari mai siffar lamba takwas akan bel ɗin raga mai motsi akai-akai kuma a haɗa su da manne na foda. Tunda zare-zaren da ke cikin CFM suna ci gaba, suna ba da ƙarin ƙarfi ga kayan haɗin gwiwa fiye da CSM. Ana amfani da shi galibi a cikin aikin pultrusion, RTM (Resin Transfer Molding), gyaran jakar matsin lamba, da kuma GMT (Glass Mat Reinforced Thermoplastics).

3.Tabarmar SamaKayayyakin FRP (Fiber Reinforced Plastics) galibi suna buƙatar Layer mai cike da resin, wanda yawanci ana samunsa ta amfani da tabarmar gilashin matsakaiciyar alkali (C-glass). Ganin cewa an yi wannan tabarmar da gilashin C, yana ba FRP juriyar sinadarai, musamman juriyar acid. Bugu da ƙari, saboda siririnsa da kuma diamita mai kyau na zare, yana iya sha ƙarin resin don samar da Layer mai cike da resin, yana rufe yanayin kayan ƙarfafa zaren gilashi (kamar roving) kuma yana aiki azaman ƙarewa a saman.

4.Tabarmar AlluraAna iya rarraba su zuwa tabarmar allurar zare da aka yanka da kuma tabarmar allurar zare mai ci gaba.

- Tabarmar allurar fiber da aka yankakkeAna yin sa ne ta hanyar yanke zare na gilashi mai tsawon mm 50, a saka su bazuwar a kan wani abu da aka sanya a baya a kan bel ɗin jigilar kaya, sannan a yi masa allura da allurar barbed. Allurar tana tura zare da aka yanka cikin abin da aka sanya, kuma sandunan kuma suna kawo wasu zare, suna samar da tsari mai girma uku. Abin da aka yi amfani da shi na iya zama yadi mai sassauƙa na gilashi ko wasu zare. Wannan nau'in tabarmar da aka yi allura tana da laushi kamar ji. Babban amfaninta ya haɗa da kayan kariya na zafi da na sauti, kayan rufi, da kayan tacewa. Hakanan ana iya amfani da shi wajen samar da FRP, amma FRP da aka samar yana da ƙarancin ƙarfi da iyakataccen ikon amfani.

- Ci gaba da filament needled MatAna yin wannan ta hanyar jefa zare-zare na gilashi mai ci gaba bazuwar a kan bel ɗin raga mai ci gaba ta amfani da na'urar shimfiɗa zare, sannan a yi allura da allon allura don samar da tabarmi mai tsarin zare mai girma uku. Ana amfani da wannan tabarmar musamman wajen samar da zaren zare mai ƙarfi na thermoplastic.

5.Tabarmar da aka dinkaZaren gilashi da aka yanka daga 50mm zuwa 60cm ana iya dinka su tare da injin dinki don samar da tabarmar zare da aka yanka ko kuma dogon tabarmar zare. Na farko zai iya maye gurbin CSM na gargajiya da aka ɗaure da manne a wasu aikace-aikace, kuma na biyun, zuwa wani lokaci, zai iya maye gurbin CFM. Fa'idodin da suka fi dacewa su ne rashin mannewa, guje wa gurɓatawa yayin samarwa, kyakkyawan aikin dasa resin, da ƙarancin farashi.

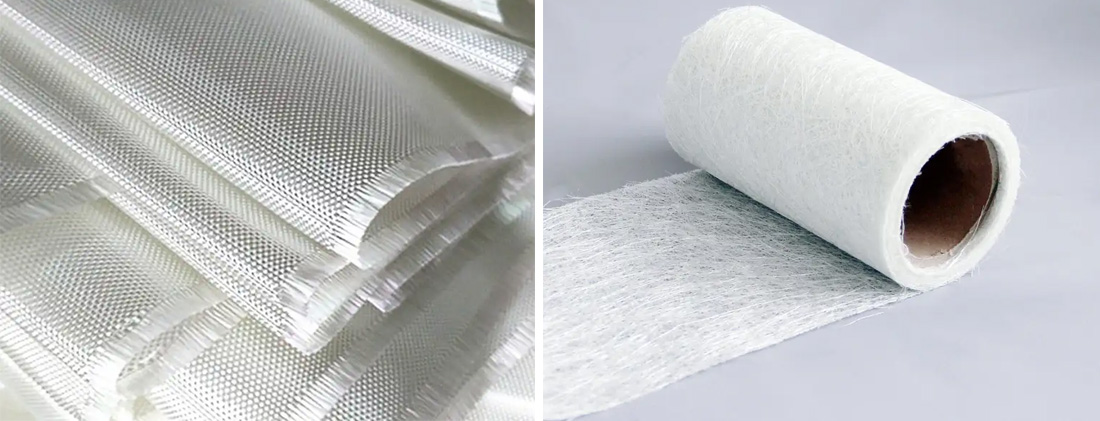

Gilashin Fiber Yadi

Mai zuwa yana gabatar da nau'ikan yadudduka na fiber gilashi daban-daban da aka saka dagazaren fiber na gilashi.

1. Gilashin ZaneAn raba zane-zanen gilashi da aka samar a kasar Sin zuwa nau'ikan da ba su da alkali (E-glass) da matsakaici-alkali (C-glass); yawancin kayayyakin da ake samarwa a kasashen waje suna amfani da zane-zanen gilashi marasa alkali na E-GLASS. Ana amfani da zane-zanen gilashi musamman don samar da nau'ikan laminates masu rufe lantarki, allunan da'ira da aka buga, jikin ababen hawa, tankunan ajiya, jiragen ruwa, molds, da sauransu. Ana amfani da zane-zanen gilashi matsakaici-alkali galibi don samar da zane-zanen marufi da aka rufe da filastik da kuma don aikace-aikacen da ba su da tsatsa. Ana tantance halayen zane-zanen ta hanyar halayen zare, yawan warp da weft, tsarin zare, da tsarin saƙa. Yawan warp da weft ana tantance su ta hanyar tsarin zare da tsarin saƙa. Haɗin yawan warp da weft da tsarin zare yana ƙayyade halayen zahiri na masana'anta, kamar nauyi, kauri, da ƙarfin karyewa. Akwai tsare-tsare guda biyar na asali na saƙa: bayyananne (kamar roving da aka saka), twill (gabaɗaya ± 45°), satin (kama da masana'anta mai jagora ɗaya), leno (babban saƙa don ragar fiber gilashi), da matts (kama da masana'anta oxford).

2.Tef ɗin Fiber na GilashiAn raba shi zuwa tef mai gefen saƙa (gefen selvage) da tef mai gefen da ba a saka ba (gefen da aka ƙera). Babban tsarin saƙa ba shi da sarkakiya. Ana amfani da tef ɗin fiber na gilashi mara alkaline sau da yawa don ƙera kayan aikin lantarki waɗanda ke buƙatar ƙarfi mai yawa da kyawawan halayen dielectric.

3.Gilashin Fiber Mai Hanya ɗaya

- Yadin Warp Mai Hanya Ɗayawani yadi ne mai sarkakiya mai sarka huɗu na satin ko dogon shaft mai saƙa da aka saka da zaren warp mai kauri da zaren weft mai kyau. Siffarsa tana da ƙarfi sosai musamman a alkiblar warp (0°).

- Akwai kumaGilashin Fiber Mai Hanya ɗaya, ana samunsa a nau'ikan saka da aka saka da kuma na saka. Ana siffanta shi da zaren saka mai kauri da kuma zaren saka mai kyau, tare da zaren zaren gilashi galibi suna fuskantar alkiblar saka, suna ba da ƙarfi mai yawa a alkiblar saka (90°).

4.Yadin Gilashi Mai Zane 3D (Yadin Sitiriyo)Yadudduka na 3D suna da alaƙa da yadudduka masu siffar ƙwallo. Sifofin tsarinsu sun samo asali daga girma ɗaya da girma biyu zuwa girma uku, suna ba wa kayan haɗin da aka ƙarfafa su da kyakkyawan aminci da daidaito, wanda hakan ya inganta ƙarfin yankewa tsakanin laminar da juriya ga lalacewar haɗin. An ƙera su don biyan buƙatun musamman na sassan sararin samaniya, jiragen sama, makamai, da ruwa, kuma aikace-aikacensu yanzu ya faɗaɗa zuwa ga haɗa da motoci, kayan wasanni, da kayan aikin likita. Akwai manyan rukunoni guda biyar: yadudduka na 3D da aka saka, yadudduka na 3D da aka saka, yadudduka na 3D da na orthogonal waɗanda ba su da tsauri, yadudduka na 3D da aka saka, da sauran nau'ikan yadudduka na 3D. Siffofin yadudduka na 3D sun haɗa da toshe, ginshiƙi, bututu, mazugi mai rami, da kuma kauri mara daidaituwa.

5. Gilashin Fiber Preform Yadi (Yadi Mai Siffa)Siffar masaku masu tsari iri ɗaya ce da siffar samfurin da aka yi niyya don ƙarfafawa, kuma dole ne a saka su a kan kayan da aka keɓe. Yadudduka masu siffar similar sun haɗa da: hula mai siffar ƙwallo, mazugi, huluna, yadudduka masu siffar dumbbell, da sauransu. Hakanan ana iya samar da siffofi marasa daidaituwa kamar akwatuna da ƙwanƙolin jirgin ruwa.

6.Yadin Gilashi Mai Kauri (Yadin Dinki Mai Kauri Ta Hanyar Gilashi)Yadin tsakiya ya ƙunshi yadudduka guda biyu masu layi ɗaya waɗanda aka haɗa su da layukan tsaye masu tsayi. Siffar sa ta giciye na iya zama mai kusurwa uku, murabba'i, ko kuma saƙar zuma.

7.Yadin da aka haɗa da Gilashi da Fiber (Tabarmar da aka saka ko Tabarmar da aka saka)Ya bambanta da yadi na yau da kullun da kuma yadda ake amfani da tabarma. Mafi yawan yadi da aka haɗa da dinki ana yin sa ne ta hanyar rufe wani yadi na zare da kuma wani yadi na zare, sannan a haɗa su wuri ɗaya don samar da yadi. Fa'idodin yadi da aka haɗa da dinki sun haɗa da:

- Zai iya ƙara ƙarfin juriya, ƙarfin hana lalacewa a ƙarƙashin tashin hankali, da ƙarfin lanƙwasa na laminates na FRP.

- Yana rage nauyinKayayyakin FRP.

- Faɗin da aka yi da lebur yana sa saman FRP ya yi laushi.

- Yana sauƙaƙa aikin ajiye hannu da inganta yawan aiki. Wannan kayan ƙarfafawa zai iya maye gurbin CFM a cikin FRP da RTM da aka ƙera, kuma yana iya maye gurbin roving da aka saka a cikin samar da bututun FRP na centrifugal.

Lokacin Saƙo: Oktoba-22-2025