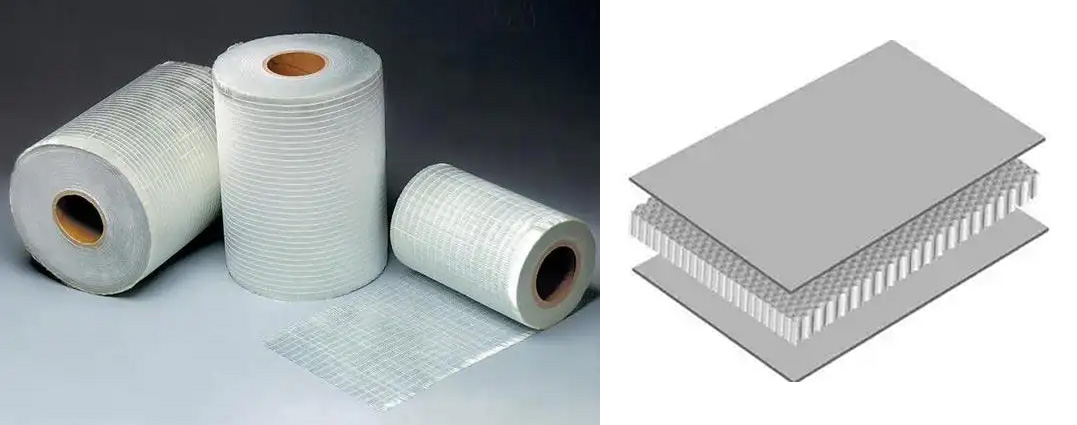

A cikin kayan haɗin kai, aikin fiberglass a matsayin babban abin ƙarfafawa ya dogara ne akan ikon haɗin fuska tsakanin zare da matrix. Ƙarfin wannan haɗin fuska yana ƙayyade ikon canja wurin damuwa lokacin da zaren gilashin ke ƙarƙashin nauyi, da kuma kwanciyar hankali na zaren gilashi lokacin da ƙarfinsa ya yi yawa. Gabaɗaya, haɗin fuska tsakanin fiberglass da kayan matrix yana da rauni sosai, wanda ke iyakance amfani da fiberglass a cikin kayan haɗin kai masu aiki sosai. Saboda haka, amfani da tsarin rufewa na wakili don inganta tsarin fuska da ƙarfafa haɗin fuska hanya ce mai mahimmanci don inganta aikin haɗin fiber gilashi.

Wani wakili mai girman girma yana samar da wani Layer na kwayoyin halitta a samanfiberglass, wanda zai iya rage tashin hankalin da ke tsakanin fuskoki, yana sa saman fiberglass ya fi hydrophilic ko oleophilic don inganta dacewa da matrix. Misali, amfani da wani sinadari mai girman da ke ɗauke da ƙungiyoyi masu aiki da sinadarai na iya ƙirƙirar haɗin sinadarai tare da saman fiberglass, yana ƙara haɓaka ƙarfin haɗin fuska.

Bincike ya nuna cewa masu auna girman nano-level za su iya shafa saman fiberglass daidai gwargwado kuma su ƙarfafa haɗin injina da sinadarai tsakanin zare da matrix, ta haka ne za su inganta halayen injina na zare. A lokaci guda, tsarin siffa mai dacewa zai iya daidaita kuzarin saman zare da kuma canza danshi na fiberglass, wanda ke haifar da manne mai ƙarfi tsakanin zare da kayan matrix daban-daban.

Tsarin shafa daban-daban kuma yana da tasiri mai mahimmanci wajen inganta ƙarfin haɗin fuska. Misali, shafa mai taimakon plasma zai iya amfani da iskar gas mai ionized don magancezaren gilashisaman, cire abubuwan halitta da ƙazanta, ƙara yawan aikin saman, don haka inganta haɗin mai aunawa da saman zare.

Kayan matrix ɗin da kansa yana taka muhimmiyar rawa a haɗin fuska. Ƙirƙirar sabbin tsarin matrix waɗanda ke da ƙarfi a fannin sinadarai ga zaruruwan gilashin da aka yi wa magani na iya haifar da gagarumin ci gaba. Misali, matrices masu yawan ƙungiyoyi masu amsawa na iya samar da ƙarin haɗin covalent mai ƙarfi tare da wakilin girma akan saman zare. Bugu da ƙari, gyara halayen danko da kwarara na kayan matrix na iya tabbatar da ingantaccen shigar da ƙwayar zare, rage gurɓatattun abubuwa da lahani a mahaɗin, waɗanda sune tushen rauni gama gari.

Ana iya inganta tsarin kera shi don inganta haɗin fuska. Dabaru kamarjiko na injinkogyaran canja wurin resin (RTM)zai iya tabbatar da daidaito da cikakken jikewa nazaruruwan gilashita hanyar matrix, kawar da aljihunan iska waɗanda zasu iya raunana haɗin gwiwa. Bugu da ƙari, yin amfani da matsin lamba na waje ko amfani da zagayar zafin jiki mai sarrafawa yayin warkewa na iya haɓaka hulɗa mai kusanci tsakanin zare da matrix, wanda ke haifar da babban matakin haɗin gwiwa da kuma haɗin gwiwa mai ƙarfi.

Inganta ƙarfin haɗin fuskoki na haɗakar zare na gilashi muhimmin fanni ne na bincike tare da amfani mai mahimmanci. Duk da cewa amfani da masu auna girma da hanyoyin rufewa daban-daban muhimmin ginshiƙi ne na wannan ƙoƙarin, akwai wasu hanyoyi da dama da ake bi don ƙara inganta aiki.

Lokacin Saƙo: Satumba-04-2025