Kayan haɗin gwiwa sun zama kayan aiki masu dacewa don ƙera jiragen sama masu ƙarancin tsayi saboda ƙarfinsu mai sauƙi, ƙarfinsu mai yawa, juriyar tsatsa da kuma laushi. A wannan zamanin tattalin arzikin ƙasa mai ƙarancin tsayi wanda ke neman inganci, tsawon lokacin batirin da kariyar muhalli, amfani da kayan haɗin gwiwa ba wai kawai yana shafar aiki da amincin jiragen sama ba, har ma shine mabuɗin haɓaka ci gaban masana'antar gaba ɗaya.

Zaren carbonkayan haɗin kai

Saboda nauyinsa mai sauƙi, ƙarfinsa mai yawa, juriyar tsatsa da sauran halaye, zare mai carbon ya zama abu mafi dacewa don ƙera jiragen sama masu ƙarancin tsayi. Ba wai kawai zai iya rage nauyin jiragen sama ba, har ma yana inganta aiki da fa'idodin tattalin arziki, kuma ya zama madadin kayan ƙarfe na gargajiya. Fiye da kashi 90% na kayan haɗin gwiwa a cikin skycars zare ne na carbon, sauran kusan kashi 10% kuma zare ne na gilashi. A cikin jiragen eVTOL, ana amfani da zare mai carbon sosai a cikin kayan gini da tsarin turawa, wanda ya kai kusan kashi 75-80%, yayin da aikace-aikacen ciki kamar katako da tsarin zama ke da kashi 12-14%, kuma tsarin baturi da kayan aikin avionics suna da kashi 8-12%.

Zarekayan haɗin gilashi

Fiberglass earned robobi (GFRP), tare da juriyar tsatsa, juriyar zafi mai yawa da ƙarancin zafi, juriyar radiation, hana harshen wuta da kuma halayen hana tsufa, suna taka muhimmiyar rawa wajen ƙera jiragen sama masu ƙarancin tsayi kamar jiragen sama marasa matuƙa. Amfani da wannan kayan yana taimakawa wajen rage nauyin jirgin, ƙara nauyin da ake buƙata, adana kuzari, da kuma cimma kyakkyawan ƙirar waje. Saboda haka, GFRP ya zama ɗaya daga cikin mahimman kayan aiki a cikin tattalin arzikin ƙasa mai ƙarancin tsayi.

A tsarin samar da jiragen sama masu ƙarancin tsayi, ana amfani da yadin fiberglass sosai wajen ƙera muhimman abubuwan gini kamar firam ɗin iska, fikafikai, da wutsiya. Halayensa masu sauƙi suna taimakawa wajen inganta ingancin jirgin da kuma samar da ƙarfi da kwanciyar hankali a tsarinsa.

Ga abubuwan da ke buƙatar ingantaccen ƙarfin raƙuman ruwa, kamar radomes da fairings, galibi ana amfani da kayan haɗin fiberglass. Misali, UAV mai tsayi mai tsayi da kuma uav na Rundunar Sojan Sama ta Amurka mai suna RQ-4 "Global Hawk" suna amfani da kayan haɗin fiber carbon don fikafikansu, wutsiya, ɗakin injin da kuma fuselage na baya, yayin da radome da fairing an yi su ne da kayan haɗin fiberglass don tabbatar da watsa sigina bayyananne.

Ana iya amfani da zane na fiberglass don yin faifan jiragen sama da tagogi, wanda ba wai kawai yana ƙara kyau da kyawun jirgin ba, har ma yana ƙara jin daɗin tafiyar. Hakazalika, a cikin ƙirar tauraron ɗan adam, ana iya amfani da zane na fiber gilashi don gina tsarin saman waje na allunan hasken rana da eriya, ta haka yana inganta kamanni da amincin aikin tauraron ɗan adam.

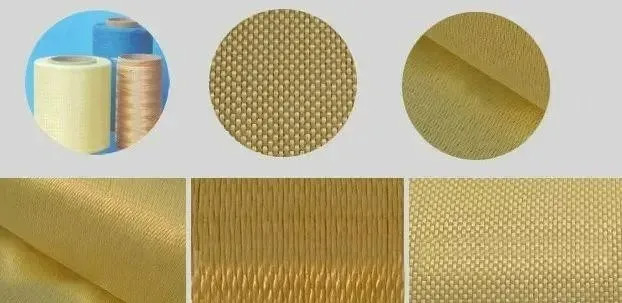

Zaren Aramidkayan haɗin kai

Kayan saƙar zuma na takarda aramid wanda aka tsara tare da tsarin hexagonal na saƙar zuma ta halitta ta bionic an girmama shi sosai saboda ƙarfinsa na musamman, taurinsa na musamman da kuma kwanciyar hankali na tsarin. Bugu da ƙari, wannan kayan yana da kyawawan abubuwan hana sauti, hana zafi da kuma hana harshen wuta, kuma hayaki da guba da ake samu yayin ƙonewa ba su da yawa. Waɗannan halaye sun sa ya mamaye matsayi mai girma a cikin manyan aikace-aikacen jiragen sama da hanyoyin sufuri masu sauri.

Duk da cewa farashin kayan saƙar zuma na takarda aramid ya fi yawa, sau da yawa ana zaɓarsa a matsayin babban kayan aiki mai sauƙi don kayan aiki masu inganci kamar jiragen sama, makamai masu linzami, da tauraron ɗan adam, musamman a cikin ƙera kayan gini waɗanda ke buƙatar ƙarfin watsawa da kuma ƙarfin juriya.

Fa'idodi masu sauƙi

A matsayin muhimmin kayan aikin tsarin fuselage, takardar aramid tana taka muhimmiyar rawa a manyan jiragen sama masu ƙarancin tsayi kamar eVTOL, musamman a matsayin sanwicin sanwicin carbon fiber na zuma.

A fannin jiragen sama marasa matuki, ana amfani da kayan saƙar zuma na Nomex (takardar aramid) sosai, ana amfani da ita a cikin harsashin fuselage, fatar fuka-fuki da gefen jagora da sauran sassa.

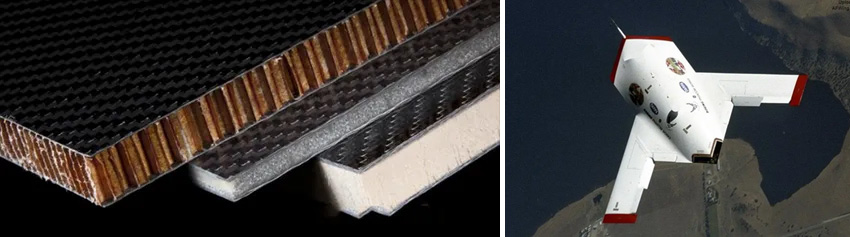

Wanikayan haɗin sandwich

Jiragen sama masu ƙarancin tsayi, kamar jiragen sama marasa matuki, baya ga amfani da kayan ƙarfafawa kamar su carbon fiber, gilashin fiber da aramid fiber a cikin tsarin kera su, ana kuma amfani da kayan tsarin sandwich kamar zuma, fim, filastik kumfa da manne kumfa sosai.

A cikin zaɓin kayan sanwici, waɗanda aka fi amfani da su sune sanwicin saƙar zuma (kamar saƙar zuma ta takarda, saƙar zuma ta Nomex, da sauransu), sanwicin katako (kamar birch, paulownia, pine, basswood, da sauransu) da sanwicin kumfa (kamar polyurethane, polyvinyl chloride, kumfa polystyrene, da sauransu).

An yi amfani da tsarin sandwich ɗin kumfa sosai a cikin tsarin firam ɗin iska na UAV saboda halayensa na hana ruwa da iyo da kuma fa'idodin fasaha na iya cike ramukan tsarin ciki na fikafikan ...

Lokacin tsara na'urorin UAV masu ƙarancin gudu, galibi ana amfani da tsarin sandwich na zuma don sassa masu ƙarancin ƙarfi, siffofi na yau da kullun, manyan saman lanƙwasa da sauƙin shimfidawa, kamar saman da ke daidaita fikafikai na gaba, saman da ke daidaita wutsiya a tsaye, saman da ke daidaita fikafikai, da sauransu. Ga sassan da ke da siffofi masu rikitarwa da ƙananan saman da ke lanƙwasa, kamar saman lif, saman rudder, saman aileron rudder, da sauransu, ana fifita tsarin sandwich na kumfa. Ga tsarin sandwich da ke buƙatar ƙarfi mafi girma, ana iya zaɓar tsarin sandwich na katako. Ga waɗancan sassan da ke buƙatar ƙarfi mai yawa da tauri mai yawa, kamar fatar fuselage, T-beam, L-beam, da sauransu, yawanci ana amfani da tsarin laminate. Kera waɗannan sassan yana buƙatar preforming, kuma bisa ga tauri da ake buƙata a cikin jirgin sama, ƙarfin lanƙwasa, tauri mai juyawa da buƙatun ƙarfi, zaɓi fiber mai ƙarfafawa, kayan matrix, abun ciki na fiber da laminate, kuma tsara kusurwoyin kwanciya daban-daban, yadudduka da jerin layuka, kuma a warke ta hanyar yanayin zafi daban-daban da matsin lamba na matsi.

Lokacin Saƙo: Nuwamba-22-2024