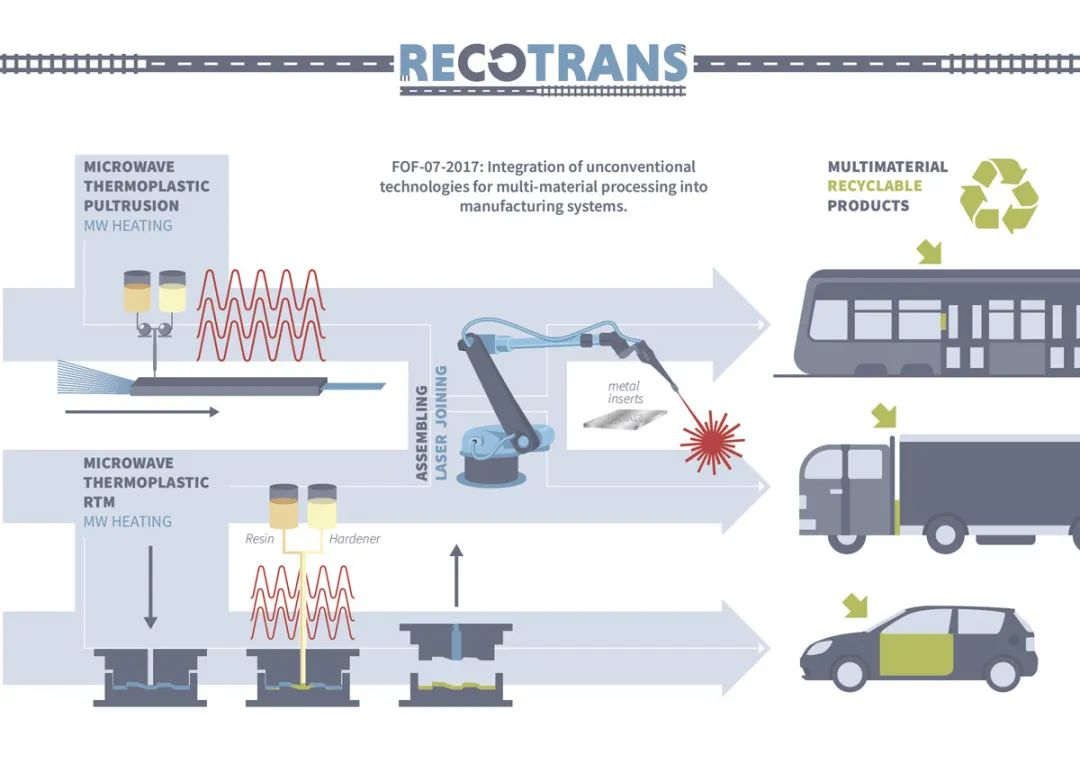

Aikin RECOTRANS na Turai ya tabbatar da cewa a cikin tsarin canza resin (RTM) da pultrusion, ana iya amfani da microwaves don inganta tsarin warkar da kayan haɗin gwiwa don rage yawan amfani da makamashi da rage lokacin samarwa, yayin da kuma taimakawa wajen samar da ingantaccen samfurin. Aikin ya kuma tabbatar da cewa ana iya amfani da fasahar laser don cimma ingantacciyar alaƙa tsakanin kayan haɗin gwiwa da ƙarfe, wanda zai iya kawar da haɗin gwiwa masu rivet waɗanda ke ƙara nauyin tsarin.

Ta hanyar haɗakar fasahar walda ta microwave da laser, aikin RECOTRANS ya ƙirƙiro sabon kayan haɗin thermoplastic kuma ya yi amfani da shi don yin sabbin sassa, ta haka kuma yana nazarin yadda za a sake amfani da wannan kayan haɗin thermoplastic.

Amfani da na'urar walda ta microwave da laser don samun kayan haɗin thermoplastic da za a iya sake amfani da su waɗanda suka dace da masana'antar sufuri

Ta hanyar haɗa fasahohin masana'antu marasa gargajiya kamar su microwave radiation da walda na laser a cikin layin samar da resin transfer molding (RTM) da pultrusion, aikin RECOTRANS ya sami samfuran da ba su da tsada kuma masu sake amfani da su waɗanda suka dace da masana'antar sufuri tare da yawan amfanin ƙasa mai yawa. Kayan haɗin tsarin kayan aiki da yawa. Idan aka kwatanta da kayan haɗin tsarin da ake amfani da su a yanzu, wannan kayan haɗin tsarin kayan aiki da yawa yana rage farashi da amfani da makamashi ta hanyar saurin pultrusion na 2m/min da kuma saurin zagayowar RTM na minti 2 (lokacin polymerization ya ragu da kashi 50%).

Aikin RECOTRANS ya tabbatar da sakamakon da ke sama ta hanyar ƙera samfuran gwaji guda uku na gaske, waɗanda suka haɗa da:

A cikin tsarin RTM, ana samun kayan haɗin thermoplastic da aka yi da zare na gilashi da kuma resin acrylic na thermoplastic ta hanyar haɗa fasahar microwave. A lokaci guda, ana amfani da walda ta laser don cimma haɗin da ke tsakanin kayan haɗin da ƙarfe. Ta wannan hanyar, ana samar da shi ga manyan motoci. Sassan samfurin tsarin dakatarwar baya na cockpit.

A cikin tsarin c-RTM, ana samun kayan haɗin thermoplastic da aka yi da kayan ƙarfafa fiber carbon da resin acrylic na thermoplastic ta hanyar haɗa fasahar microwave, ta haka ne ake samar da bangarorin ƙofofin mota.

A cikin tsarin pultrusion, ana samun wani abu mai hadewa da aka yi da kayan da aka ƙarfafa da zare na gilashi da kuma resin acrylic na thermoplastic ta hanyar haɗa fasahar microwave, ta haka ne ake samar da allon ciki na masana'antar jigilar jirgin ƙasa, kayan haɗin gwiwa da kuma haɗin da ke tsakanin ƙarfe ta hanyar walda ta laser.

Bugu da ƙari, aikin yana amfani da kashi 50% na kayan da aka sake yin amfani da su don yin aikin nuna hannun ƙofa don tabbatar da sake amfani da sabon kayan haɗin thermoplastic da aka haɓaka ta hanyar fasahar microwave da laser walda.

Lokacin Saƙo: Nuwamba-11-2021