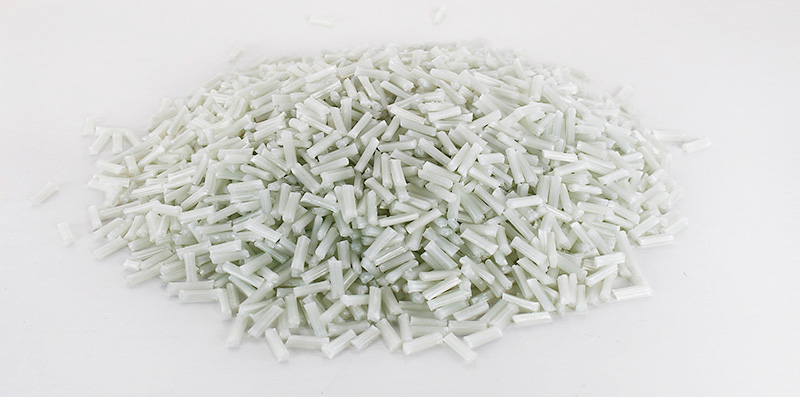

Shirye-shiryen Kayan Danye

Kafin samar da dogon lokacihaɗakar polypropylene da aka ƙarfafa da fiberglass, ana buƙatar isasshen shiri na kayan masarufi. Manyan kayan sun haɗa da resin polypropylene (PP), dogon fiberglass (LGF), ƙari da sauransu. Resin polypropylene shine kayan matrix, dogayen zaruruwan gilashi azaman kayan ƙarfafawa, ƙari gami da masu plasticizers, masu daidaita abubuwa, man shafawa, da sauransu, waɗanda ake amfani da su don inganta halayen sarrafawa da halayen injiniya na kayan.

Shigar da Fiberglass

A matakin shigar da zaren gilashi, ana shigar da dogayen zaren gilashi cikin resin polypropylene. Wannan matakin yawanci yana amfani da hanyar kafin a shigar da zaren ko kuma hadawa kai tsaye, ta yadda zaren gilashin zai cika da zaren gilashi, wanda hakan zai sa a fara shirya kayan hadewa daga baya.

Watsawar Fiberglass

A cikin matakin watsawar fiberglass, ana ƙara haɗa zaruruwan gilashi masu tsayi da aka shigar da su tare daresin polypropylenea cikin wurin haɗawa don tabbatar da cewa zare-zaren sun warwatse a cikin resin. Wannan matakin yana da mahimmanci ga aikin kayan haɗin, kuma yana da mahimmanci a tabbatar da cewa zaren ya warwatse sosai a cikin resin.

Allura Molding

A lokacin da ake yin allurar, ana yin amfani da kayan haɗin da aka haɗa sosai ta hanyar injin ƙera allura. A lokacin da ake yin allurar, ana dumama kayan kuma a saka su cikin mold ɗin, sannan a sanyaya su don samar da wani samfurin haɗin da ke da takamaiman siffa da girma.

Maganin Zafi

Maganin zafi muhimmin bangare ne na tsarin samar da zafi mai tsawohaɗakar polypropylene da aka ƙarfafa da fiberglassTa hanyar maganin zafi, ana iya ƙara inganta halayen injina da kwanciyar hankali na haɗin. Maganin zafi yawanci ya ƙunshi matakan dumama, riƙewa da sanyaya don cimma ingantaccen aikin haɗin.

Sanyaya da girma

A matakin sanyaya da siffa, kayan haɗin da aka yi wa zafi ana sanyaya su ta hanyar kayan sanyaya, ta yadda samfuran za su kasance masu siffar siffar. Wannan matakin yana da mahimmanci don tabbatar da daidaiton girma da ingancin saman samfurin.

Bayan sarrafawa

Bayan sarrafawa shine ƙarin sarrafa samfuran da aka sanyaya da siffa, kamar yankewa, niƙawa, da sauransu, don cire burrs da lahani a saman samfuran, da kuma inganta bayyanar da daidaiton girma na samfuran.

Duba Inganci

A ƙarshe, ana duba haɗin polypropylene mai ƙarfi da aka yi da fiber ɗin gilashi don tabbatar da inganci. Binciken inganci ya haɗa da duba kamanni, auna girma, gwajin kadarorin injiniya, da sauransu, don tabbatar da cewa samfuran sun cika buƙatun ƙira da ƙa'idodi masu dacewa. Binciken inganci zai iya tabbatar da cewa samfuran haɗin suna da kyakkyawan aiki da kwanciyar hankali.

Tsarin samar da dogon lokacifiberglassHaɗin polypropylene masu ƙarfi sun haɗa da matakan shirya kayan da aka yi amfani da su, shigar fiberglass, watsa fiberglass, ƙera allura, maganin zafi, sanyaya da siffantawa, bayan an yi amfani da kayan da kuma duba inganci. Ta hanyar cikakken iko da aiwatar da wannan tsari, ana iya samar da samfuran haɗin polypropylene masu ƙarfi masu ƙarfi masu inganci.

Lokacin Saƙo: Oktoba-14-2024