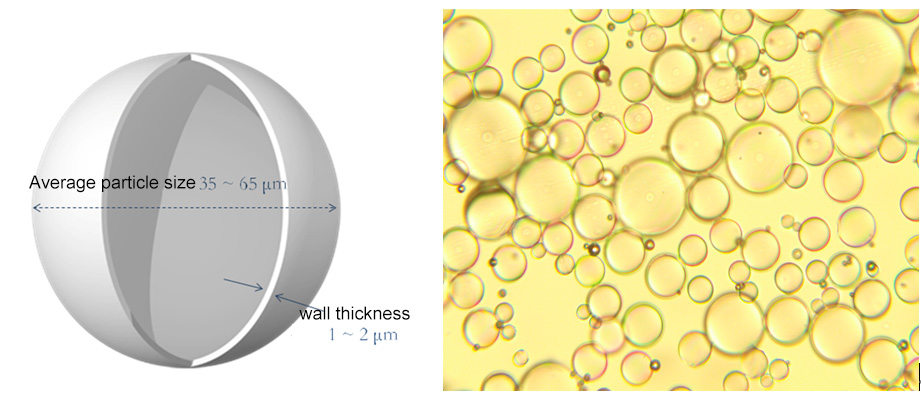

Ƙara beads ɗin gilashi mara zurfi a cikin samfuran roba na iya kawo fa'idodi da yawa:

1, Rage nauyi

Kayayyakin roba kuma suna zuwa ga hanya mai sauƙi da dorewa, musamman amfani da ƙananan beads na roba, daga yawan roba na yau da kullun na 1.15g/cm³ ko makamancin haka, ƙara sassa 5-8 na ƙananan beads, wanda aka rage zuwa 1.0g/cm³ (wanda aka fi sani da "shawagi a kan ruwa"), akwai wani matakin ƙwarewar R&D na abokan ciniki ta hanyar ƙara ƙananan beads zai zama 0.9 ko ma 0.85g/cm³, wanda ke rage yawan roba, takalma da irin wannan yanayi kafin rage nauyi na 20% ko makamancin haka. A halin yanzu, wasu abokan ciniki waɗanda ke da takamaiman ikon R&D za su sa yawan ya zama 0.9 ko ma 0.85g/cm³ ta hanyar ƙara ƙananan beads, wanda ke rage yawan roba sosai, kuma nauyin takalman zai ragu da kusan 20% a cikin irin wannan yanayi kamar da.

2, Rufin zafi

Tsarin ramin da ke cikin gilashin da ba su da ramuka yana ba wa beads ƙarancin ƙarfin lantarki na thermal, domin ƙaramin ƙarfin lantarki na thermal da aka ƙara wa kayan roba na iya yin tasiri mai kyau na kariya daga zafi, kamar a cikin faifan kariya daga thermal, allunan kariya daga thermal da sauran kayayyakin da ake amfani da su.

3, Rage yawan sauti da kuma rage hayaniya

A cikin gilashin da babu komai akwai siririn iskar gas, raƙuman sauti a cikin wannan ɓangaren za su yi rauni, a wani ƙarin ƙari don yin tasiri mai kyau na shaƙar sauti da rage hayaniya.

4, Kyakkyawan kwanciyar hankali

Gilashin tushe na beads shine gilashi mai ƙarancin yawan faɗaɗa zafi, kyakkyawan kwanciyar hankali idan aka fuskanci girgizar zafi, wanda aka ƙara wa kayan roba zai ba samfurin ingantaccen kwanciyar hankali.

Shawarwari don amfani a cikin sarrafawa:

1, kayan aikin sarrafa kayayyakin roba gabaɗaya suna da ƙarfi, mai buɗewa, mai fitar da sukurori ɗaya, da sauransu, saboda beads ɗin kayan gilashi bango ne na ƙwayoyin da ke da tauri, a cikin rawar da ƙarfin yankewa na injiniya zai lalace kaɗan, beads ɗin za su rasa aikinsa na musamman bayan sun karye.

2, beads ɗin gilashi masu rami suna da samfura daban-daban da sigogi masu dacewa, bisa ga kayan aiki daban-daban da buƙatun samfura don zaɓar samfuran beads masu dacewa yana da matuƙar mahimmanci, St. Leite ya ba da shawarar amfani da HL38, HL42, HL50, HS38, HS42 a cikin samfuran roba.

3, idan aka yi amfani da shi a cikin injin tacewa, akwai na'urar juyawa a kan abin da aka yanke na roba, ƙarfin yankewa ba za a iya guje masa ba, don haka gwargwadon iyawa don rage lokacin da aka yanke a cikin tacewa, ana ba da shawarar a ƙara a cikin sake tacewa don tabbatar da cewa an rarraba beads ɗin da aka ƙara a cikin tacewa na minti 3-5 daidai gwargwado; a cikin injin tacewa, tazara mai birgima da lokacin tace beads suna da babban tasiri, ana ba da shawarar cewa tazara mai birgima daga 2mm, lokacin tacewa bai kamata ya yi tsayi da yawa ba; Ƙarfin yankewa gabaɗaya na mai fitar da sukurori ɗaya ƙanana ne, a takaice dai, tasirin da ke kan ƙananan beads ƙanana ne, ana ba da shawarar a ƙara zafin fitarwa da 5 ℃, rage ɗanɗanon kayan ya fi dacewa da ƙera extrusion, rage ƙananan beads ɗin da suka karye.

Lokacin Saƙo: Yuli-21-2023