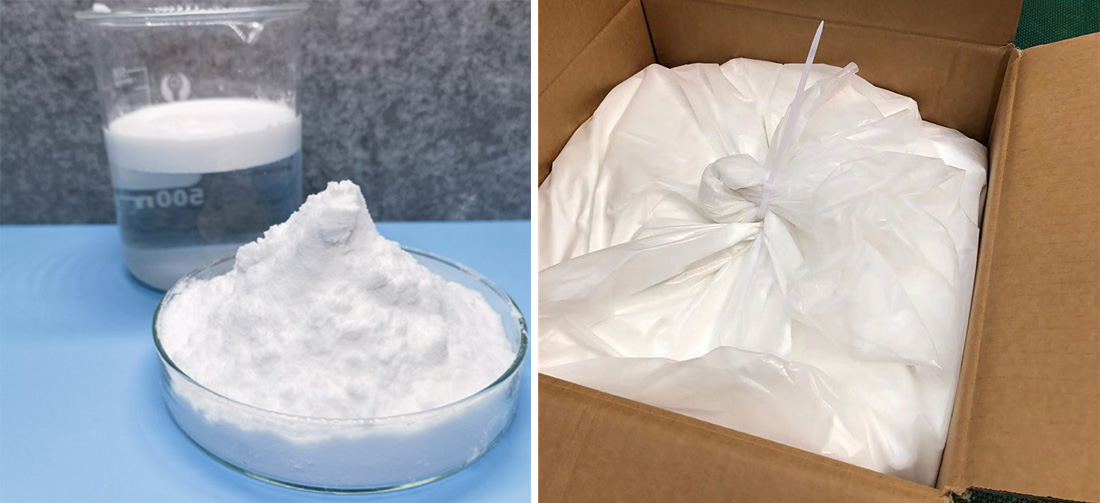

Ƙananan ƙananan gilashin gilashida kayan haɗin gwiwar su

Kayan aiki masu ƙarfi masu ƙarfi don amfani da zurfin teku gabaɗaya sun ƙunshi kafofin watsa labarai masu daidaita buoyancy (ƙananan microspheres) da kuma haɗakar resin mai ƙarfi. A duniya, waɗannan kayan suna samun yawan 0.4-0.6 g/cm³ da ƙarfin matsi na 40-100 MPa, kuma an yi amfani da su sosai a cikin kayan aiki daban-daban na zurfin teku. Ƙananan microspheres kayan gini ne na musamman da aka cika da iskar gas. Dangane da abun da suka ƙunsa, galibi an raba su zuwa ƙananan microspheres na halitta da ƙananan microspheres na halitta. Bincike kan ƙananan microspheres na halitta ya fi aiki, tare da rahotannin da suka haɗa da ƙananan polystyrene da ƙananan polymethyl methacrylate. Kayan da ake amfani da su don shirya ƙananan microspheres na halitta galibi sun haɗa da gilashi, yumbu, borates, carbon, da cenospheres na toka.

Ƙananan Gilashin da ke da Hollow: Ma'ana da Rarrabawa

Ƙananan gilashin da ba su da haske wani sabon nau'in kayan micropowder ne mai siffar zobe mara ƙarfe wanda ba na halitta ba, tare da kyawawan halaye kamar ƙaramin girman barbashi, siffar siffar zobe, nauyi mai sauƙi, rufin sauti, rufin zafi, juriyar lalacewa, da juriyar zafin jiki mai yawa. An yi amfani da ƙananan gilashin da ba su da haske sosai a cikin kayan sararin samaniya, kayan ajiyar hydrogen, kayan buoyancy mai ƙarfi, kayan rufin zafi, kayan gini, da fenti da rufi. Gabaɗaya an raba su zuwa rukuni biyu:

① Cenospheres, waɗanda galibi suka ƙunshi SiO2 da ƙarfe oxides, ana iya samun su daga tokar ƙuda da ake samarwa yayin samar da wutar lantarki a cikin tashoshin wutar lantarki na zafi. Duk da cewa cenospheres ba su da tsada, suna da rashin tsarki, rarrabawar girman barbashi mai faɗi, musamman ma, yawan barbashi gabaɗaya ya fi 0.6 g/cm3, wanda hakan ya sa ba su dace da shirya kayan buoyancy don aikace-aikacen teku mai zurfi ba.

② Gilashin da aka haɗa da na'urorin lantarki, waɗanda ƙarfinsu, yawansu, da sauran halayensu na kimiyyar lissafi za a iya sarrafa su ta hanyar daidaita sigogin tsari da kuma tsarin kayan aiki. Duk da cewa sun fi tsada, suna da fa'idodi da yawa.

Halaye na Ƙananan Gilashin Hollow

Yaɗuwar amfani da ƙananan ƙwayoyin gilashi masu rami a cikin kayan buoyancy mai ƙarfi ba za a iya raba su da kyawawan halayensu ba.

①Ƙananan ƙananan gilashin gilashisuna da tsarin ciki mai zurfi, wanda ke haifar da nauyi mai sauƙi, ƙarancin yawa, da ƙarancin ikon sarrafa zafi. Wannan ba wai kawai yana rage yawan kayan haɗin kai ba ne kawai, har ma yana ba su kyakkyawan rufin zafi, rufin sauti, rufin lantarki, da kuma kayan gani.

② Ƙananan gilashin gilashi masu rami suna da siffar zagaye, suna da fa'idodin ƙarancin porosity (cikakken cikawa) da ƙarancin shaƙar polymer ta hanyar ƙwallo, don haka ba su da tasiri sosai kan kwararar matrix da ɗanko. Waɗannan halaye suna haifar da rarraba damuwa mai ma'ana a cikin kayan haɗin, ta haka suna inganta taurinsa, taurinsa, da kwanciyar hankali na girma.

③ Ƙananan gilashin gilashi masu rami suna da ƙarfi sosai. Ainihin, ƙananan gilashin gilashi masu rami suna da sirara, an rufe su da gilashi a matsayin babban ɓangaren harsashi, suna nuna ƙarfi mai yawa. Wannan yana ƙara ƙarfin kayan haɗin gwiwa yayin da yake riƙe da ƙarancin yawa.

Hanyoyin Shiri na Microspheres na Gilashi Mai Ruwa

Akwai manyan hanyoyin shiri guda uku:

① Hanyar foda. Da farko ana niƙa gilashin matrix ɗin, ana ƙara wani abu mai kumfa, sannan a wuce waɗannan ƙananan ƙwayoyin ta cikin tanda mai zafi. Lokacin da ƙwayoyin suka yi laushi ko suka narke, ana samar da iskar gas a cikin gilashin. Yayin da iskar gas ɗin ke faɗaɗa, ƙwayoyin za su zama dunƙule-dunƙule masu ramuka, waɗanda ake tattarawa ta amfani da mai raba iskar cyclone ko matatar jaka.

② Hanyar ɗigon ruwa. A wani zafin jiki, ana fesawa ko kuma a dumama ruwan da ke ɗauke da sinadarin da ke narkewa a ƙasa a cikin tanda mai zafi, kamar yadda ake yi a cikin shirye-shiryen ƙananan ƙwayoyin halitta masu alkaline.

③ Hanyar gel busasshe. Wannan hanyar tana amfani da alkoxides na halitta a matsayin kayan aiki kuma ta ƙunshi hanyoyi guda uku: shirya gel busasshe, niƙa, da kuma kumfa a zafin jiki mai yawa. Duk hanyoyin guda uku suna da wasu matsaloli: hanyar foda tana samar da ƙarancin yawan samuwar beads, hanyar digo tana samar da microspheres marasa ƙarfi, kuma hanyar gel busasshe tana da tsadar kayan aiki mai yawa.

Tsarin Kayan Haɗin Gilashin Hollow Microsphere da Hanyar Haɗaka

Don samar da kayan aiki mai ƙarfi mai ƙarfi tare daƙananan ƙwayoyin gilashi masu rami, kayan matrix dole ne su mallaki kyawawan halaye, kamar ƙarancin yawa, ƙarfi mai yawa, ƙarancin ɗanko, da kyakkyawan mai tare da microspheres. Kayan matrix da ake amfani da su a yanzu sun haɗa da epoxy resin, polyester resin, phenolic resin, da silicone resin. Daga cikin waɗannan, epoxy resin shine mafi yawan amfani a cikin samarwa na ainihi saboda ƙarfinsa mai yawa, ƙarancin yawa, ƙarancin sha ruwa, da ƙarancin raguwar narkewa. Ana iya haɗa ƙananan microspheres na gilashi da kayan matrix ta hanyar tsarin ƙira kamar siminti, shigar da injin tsotsa, gyaran ruwa, tara ƙwayoyin cuta, da gyaran matsi. Yana da mahimmanci a jaddada cewa domin inganta yanayin da ke tsakanin ƙananan microspheres da matrix, saman ƙananan microspheres kuma yana buƙatar a gyara shi, ta haka ne inganta aikin kayan haɗin gaba ɗaya.

Lokacin Saƙo: Disamba-15-2025