Kayan ciki masu tsada, hular gashi mai sheƙi, hayaniya mai ban mamaki… duk suna nuna girman kai na manyan motocin wasanni, waɗanda da alama suna nesa da rayuwar talakawa, amma ka sani? A gaskiya ma, kayan ciki da hular waɗannan motocin an yi su ne da kayayyakin fiberglass.

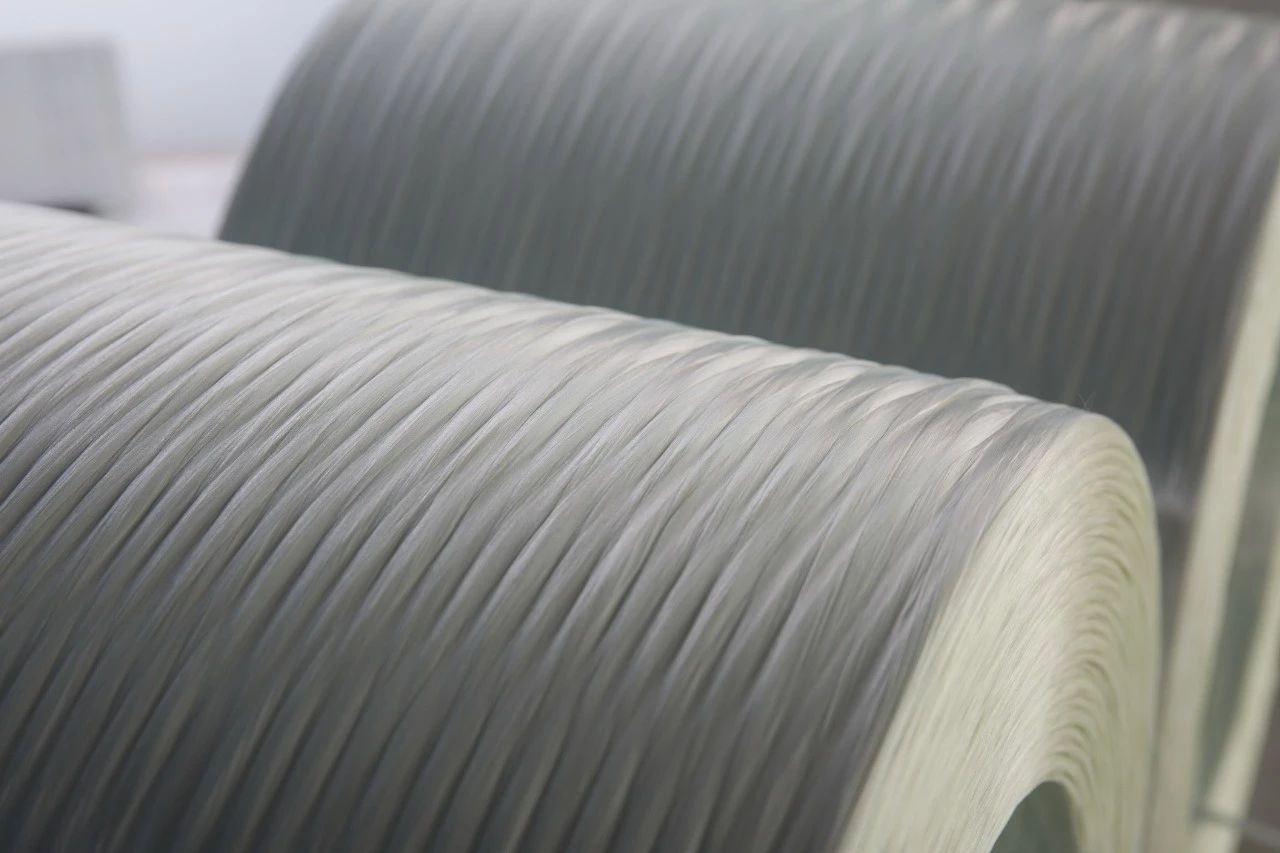

Baya ga manyan motoci, mutane na yau da kullun suna tuƙa motoci da manyan motoci waɗanda ke jigilar kayayyaki, waɗanda duk an yi su da zare na gilashi. Ana iya cewa aikin amfani da zare na gilashi za a iya tsawaita shi ba tare da wani lokaci ba.

A halin yanzu, kayan haɗin kayan aikin mota masu ƙarfin fiber gilashi za a iya raba su zuwa nau'i biyu: thermoplastic da thermosetting. Tsarin samarwa na biyu ya bambanta, kuma amfaninsu ma ya bambanta. Ana amfani da samfuran fiber gilashi masu ƙarfin thermosetting don LFT galibi don sassan ciki na mota, kamar maƙallan panel na kayan aiki, akwatunan taya na ajiya, maƙallan gaba da sauran abubuwan da ba na atomatik ba; samfuran fiberglass na thermoset SMC galibi ana amfani da su don murfin mota, bumpers, da masu raba tankin mai. Murfin zafi da sauran sassan tsarin mota.

Tare da ci gaban masana'antar motoci da kuma haɓaka manufofin kiyaye makamashi da kare muhalli, motoci masu sauƙi sun zama yanayin gabaɗaya. Yawan man fetur na mota ya dogara ne akan canjin injin da jimlar nauyin motar. Dangane da kiyaye inganci, aiki da farashin motar gabaɗaya, rage nauyin motar zai iya ƙara ƙarfin fitarwa da sarrafawa yadda ya kamata, rage yawan amfani da mai, da rage fitar da hayaki. Bincike ya nuna cewa ga kowane kashi 10% na raguwar nauyin abin hawa, ana iya rage yawan amfani da mai da kashi 6-8%. Sauya ƙarfe na gargajiya da zare na gilashi na iya rage nauyin motar sosai.

Kayayyakin SMC muhimmin bangare ne na sassan motoci. Yadda ake rage nauyin motoci ta hanyar inganta aikinsu matsala ce mai matukar muhimmanci ga masana'antun motoci su magance.

A halin yanzu, hanyar da aka fi sani a masana'antar ita ce maye gurbin kayan cikawa na gargajiya da beads na gilashi masu rami, ta haka rage yawan zanen, don cimma tasirin rage nauyin motar. Amma matsalar da wannan ke kawowa ita ce cewa kayan aikin injiniya na kayan suma suna raguwa. Saboda haka, don tabbatar da cewa kayan aikin injiniya suna da ƙarancin yawa, ana iya amfani da zare na gilashi don samar da yanayi mafi girma na injiniya. Kayayyakin SMC da aka ambata a sama sun ƙunshi zare na gilashi, cikawa da resin.

Kayayyakin fiber na gilashi don SMC masu ƙarfi da kuma siffofin saman. Samfurin zai iya biyan buƙatun kaddarorin injiniya da halayen saman matakin A a lokaci guda, kuma ya dace da samar da sassan bayyanar motoci da sassan tsarin. Idan aka kwatanta da masu fafatawa a masana'antu a ƙarƙashin yanayi iri ɗaya, aikin injiniya gabaɗaya ya ƙaru da kashi 20%, wanda ke ba da mafita ga matsalar lalacewar aikin injiniya na SMC mai ƙarancin yawa.

Kamar waɗannan motocin wasanni masu kayatarwa, buƙatun ƙarfi da kamanni sun fi na motoci na yau da kullun girma, musamman don kamanni da santsi. SMC tana amfani da fiber gilashi 456 a matsayin sabon nau'in samfurin fiber gilashi don sassan motoci, wanda zai iya biyan buƙatun saman A-level na abokin ciniki, wato, saman madubi, kuma haskensa ya isa ya dace da matsayin manyan motoci.

Baya ga kayayyakin SMC, kayan thermoplastic da aka ƙarfafa da fiber gilashi suma suna iya taka muhimmiyar rawa a fagen maye gurbin ƙarfe da filastik a cikin motoci. Zaren LFT mai aiki mai ƙarfi 362H galibi ana amfani da shi a cikin sassan motoci kamar madubin baya, murfin da ke hana sauti, maƙallan panel na kayan aiki, da sauransu.

Fasahar LFT tana da manyan buƙatu don sarrafa zare, musamman juriyar sawa ta zare. Gashin a kowace kilogiram na 362H yana da ƙasa sosai. Dr. Fan Jiashu na Cibiyar Bincike da D ta Samfura ya tabbatar da hakan ta hanyar kwatantawa ta gwaji. Lokacin da ya saita danshi zuwa 50%, gashin a kowace kilogiram na 362H ya yi ƙasa sosai fiye da na samfurin kwatantawa; lokacin da danshi ya tashi zuwa 75%, gashin duk samfuran yana ƙaruwa, wanda ke ƙayyade halayen mai auna girman zaren da kansa. Amma abin mamaki shine lokacin da danshi ya kai 75%, gashin 362H har yanzu yana ƙasa da na ƙungiyar sarrafawa, wanda ke nuna kyakkyawan juriyar gogewa na 362H.

Ba wai kawai ba, halayen injina na 362H suma suna da ƙarfi da ƙarfi mai yawa. Da shi, motar za ta fi jure wa haɗurra idan wani mummunan tasiri ya faru. Ba za ta yi "ƙarfe" kamar ƙarfe ba, kuma ba za ta "ji rauni" cikin sauƙi ba. Wannan iri ɗaya ne da saman 362H. Maganin siffa ta musamman ba zai iya rabuwa ba. Ci gaban zaren kai tsaye mai ƙarfi da ingantaccen LFT mai ƙarfi don PP 362H yana ƙara inganta tsarin samfurin zaren kai tsaye don LFT. Babban watsawa da mai mai yawa sun cika buƙatun abokin ciniki don iya sarrafawa.

Lokacin Saƙo: Yuni-17-2021