(1) Kayayyakin kayan aiki masu hana zafi

Babban hanyoyin tsari na gargajiya don haɗakar ayyukan aiki masu inganci a sararin samaniyakayan da ke rufe zafisune RTM (Resin Transfer Molding), gyaran fuska, da kuma layup, da sauransu. Wannan aikin ya rungumi sabon tsarin gyaran fuska da yawa.

Tsarin RTM:

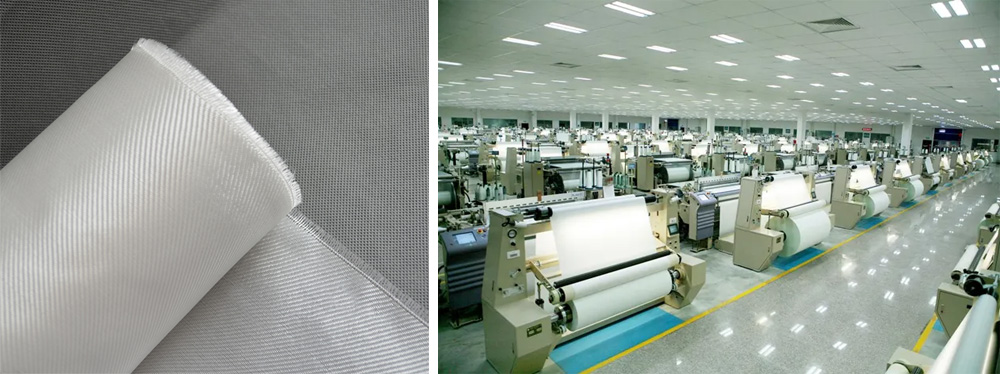

① Sanya zane mai zare: ana saka zane mai zare mai zare da aka shirya a cikin ramin mold a lokaci guda;

② Allurar Resin: Ana haɗa resin da mai kara kuzari a cikin mahaɗin da ke tsaye a gaban bindigar allurar sannan a allurar a cikin ramin mold da aka rufe da zane mai zare.

③ Gyaran Resin: ana dumama ramin mold domin hanzarta warkar da resin;

(iv) Rufe samfurin: Bayan an wartsake kuma an ƙera shi, ana buɗe masakar don samun ɓangaren haɗakar ƙarshe.

Bayan aikin RTM (Resin Transfer Molding), ana sarrafa zane mai zare na quartz kuma a sanya shi da harsashin ƙarfe, kuma samfurin bayan saitin ya cancanci bayan gwajin aiki, wanda shine samfurin da aka gama.

(2) Kayan haɗin da aka haɗa da raƙuman ruwa masu haske

An ƙarfafa zaren quartzHaɗaɗɗun na'urorin haɗin yumbu masu haske waɗanda aka shirya ta hanyar hanyar fasawa ta hanyar precursor impregnation impregnation (PIP). Hanyar PIP ita ce amfani da precursor impregnated fiber precursor, sannan pyrolysis, samar da matrix na quartz fiber da aka sanya a cikin wuraren da aka riga aka saka a kan billet, a cikin billet bayan feshi fenti don dubawa, dubawa da cancantar samfurin da aka gama. Domin tabbatar da cewa saman kayan zafin da ake buƙata ya yi ƙasa da tsarin sintering na gargajiya, zai iya rage lalacewar zaruruwan quartz, kuma yana da halaye na siffanta kusa da net, musamman dacewa don shirya manyan abubuwan kayan da aka riga aka saka.

(3) Kayayyakin kariya na musamman

Thezane mai zare mai siffar quartzZa a shirya resin a cikin ramin mold, za a allurar da resin a cikin ramin mold don ya cika da ramin mold na zare, yana dumama ramin mold don hanzarta warkar da resin, gyaran resin, buɗe mold kuma zai iya samun kayan aikin kariya na musamman na ƙarshe.

Lokacin Saƙo: Nuwamba-11-2024