Gogewar FRP Mai Tsafta

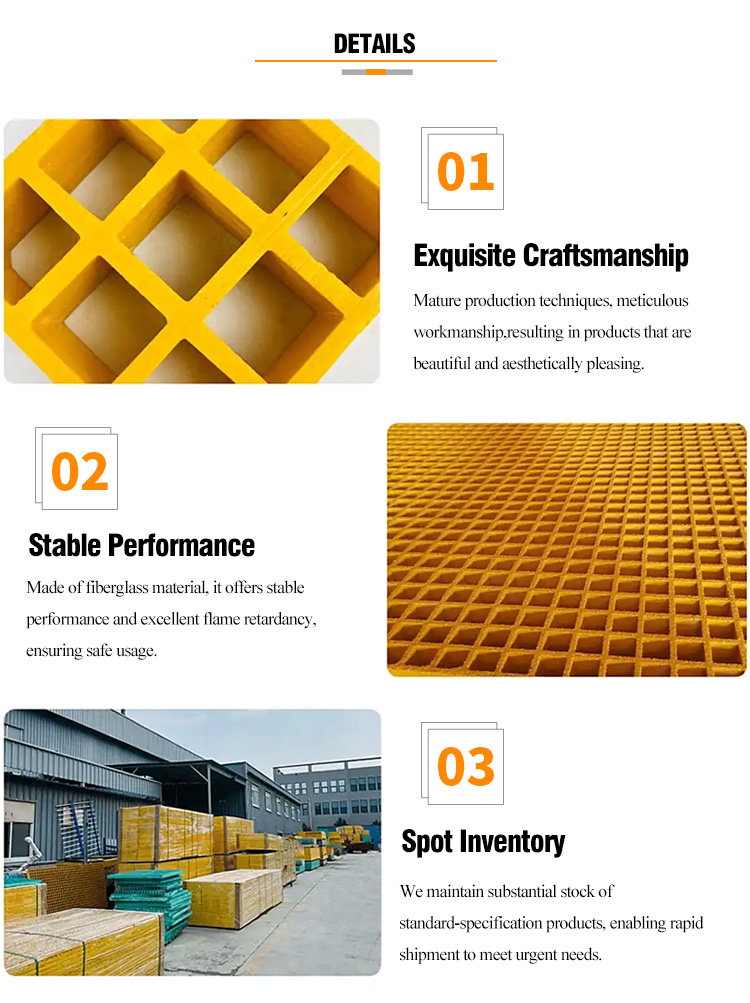

Gabatarwa ga Kayayyakin Rage Fitar FRP

Ana yin grating ɗin fiberglass mai ƙarfi ta amfani da tsarin pultrusion. Wannan dabarar ta ƙunshi ci gaba da jan cakuda zaruruwan gilashi da resin ta cikin mold mai zafi, yana samar da siffofi masu ƙarfi da dorewa. Wannan hanyar samarwa mai ci gaba tana tabbatar da daidaiton samfura da inganci mai girma. Idan aka kwatanta da dabarun masana'antu na gargajiya, tana ba da damar samun ingantaccen iko akan abun ciki na fiber da rabon resin, ta haka ne ke inganta halayen injiniya na samfurin ƙarshe.

Abubuwan da ke ɗauke da kaya suna da siffofi masu siffar I ko T waɗanda aka haɗa ta hanyar sandunan zagaye na musamman a matsayin sandunan giciye. Wannan ƙira tana cimma daidaito mafi kyau tsakanin ƙarfi da nauyi. A fannin injiniyan gine-gine, ana san I-beams sosai a matsayin mambobi masu inganci na tsarin gini. Tsarin su yana tattara mafi yawan kayan a cikin flanges, yana ba da juriya ta musamman ga matsin lamba mai lanƙwasa yayin da yake riƙe da ƙarancin nauyin kai.

Manyan Amfani da Halayen Aiki

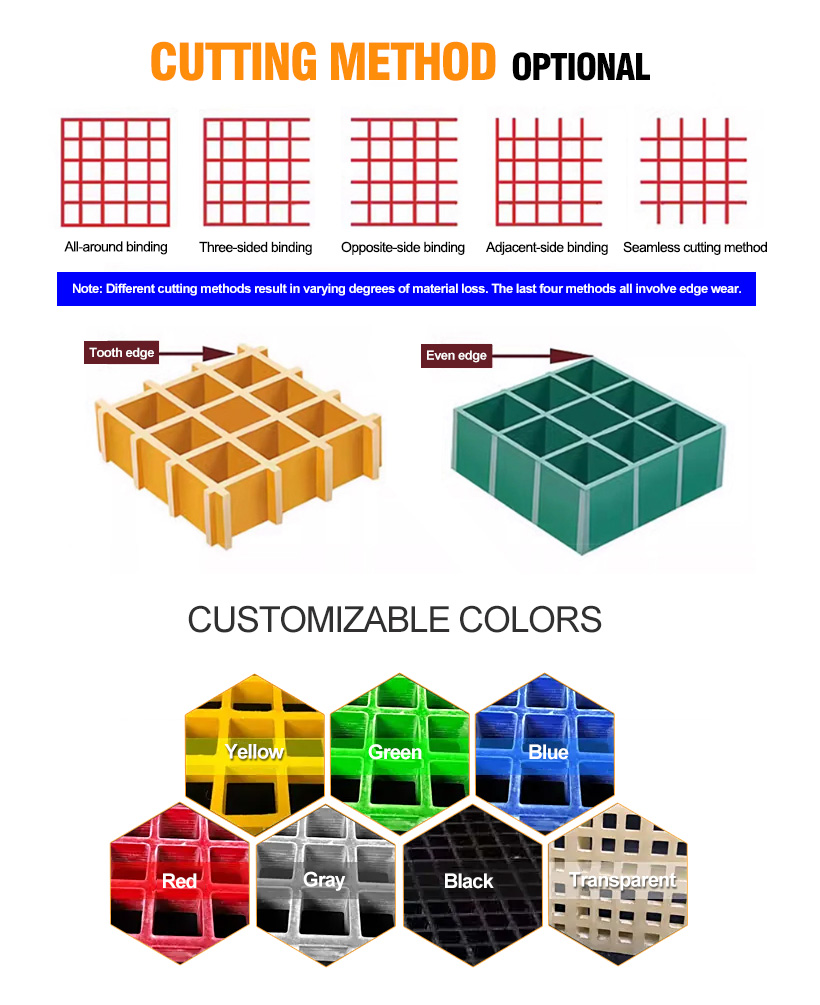

A matsayin kayan haɗin gwiwa mai ƙarfi, filastar fiberglass (FRP) grating yana taka muhimmiyar rawa a aikace-aikacen masana'antu da kayayyakin more rayuwa na zamani. Idan aka kwatanta da kayan ƙarfe ko siminti na gargajiya, filastar FRP tana ba da fa'idodi daban-daban kamar juriyar tsatsa ta musamman, rabo mai ƙarfi-da-nauyi, halayen rufin lantarki, da ƙarancin buƙatun kulawa. Bugu da ƙari, ana ƙera filastar FRP ta amfani da tsarin pultrusion don samar da bayanan martaba na "I" ko "T" a matsayin membobi masu ɗaukar nauyi. Kujerun sanda na musamman suna haɗa sandunan haɗin gwiwa, kuma ta hanyar dabarun haɗuwa na musamman, ana ƙirƙirar allon da aka huda. Fuskar filastar da aka zuga tana da ramuka don juriyar zamewa ko kuma an rufe ta da ƙarewar matte mai hana zamewa. Dangane da buƙatun aikace-aikacen aiki, ana iya haɗa faranti masu siffar lu'u-lu'u ko faranti masu rufi da yashi zuwa grating don ƙirƙirar ƙirar sel mai rufewa. Waɗannan halaye da ƙira sun sa ya zama madadin da ya dace ga masana'antun sinadarai, wuraren kula da ruwan sharar gida, tasoshin wutar lantarki, dandamali na teku, da sauran wurare waɗanda ke buƙatar juriya ga muhallin lalata ko buƙatun juriya mai tsauri.

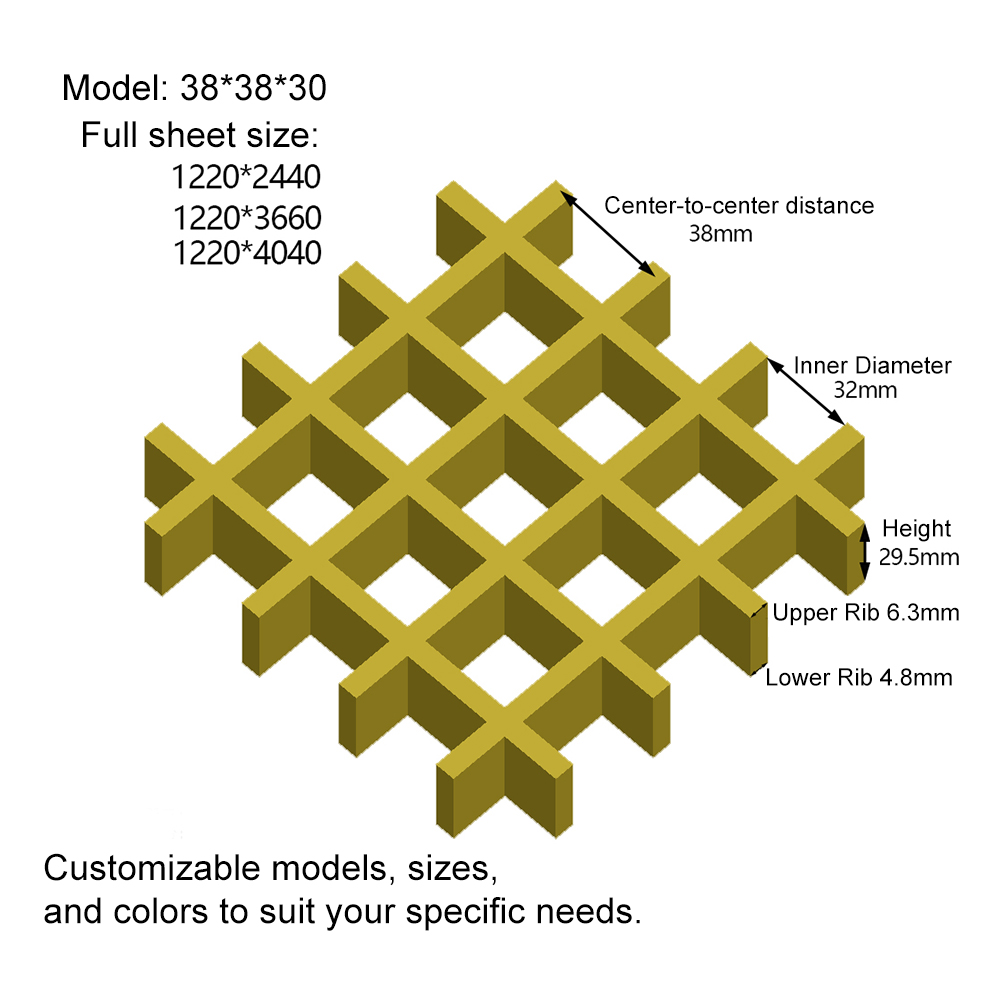

Siffar Tantanin Halitta daBayanan Fasaha

1. Tsarin Fiberglass Mai Tsabta - Takaitattun Siffofin Samfurin T

2. Tsarin Samfurin FRP Mai Tsari ...

| Samfuri | Tsawo A (mm) | Faɗin Gefen Sama B (mm) | Faɗin Buɗewa C (mm) | % na Buɗewar Yanki | Nauyin Ka'idar (kg/m²) |

| T1810 | 25 | 41 | 10 | 18 | 13.2 |

| T3510 | 25 | 41 | 22 | 35 | 11.2 |

| T3320 | 50 | 25 | 13 | 33 | 18.5 |

| T5020 | 50 | 25 | 25 | 50 | 15.5 |

| I4010 | 25 | 15 | 10 | 40 | 17.7 |

| I4015 | 38 | 15 | 10 | 40 | 22 |

| I5010 | 25 | 15 | 15 | 50 | 14.2 |

| I5015 | 38 | 15 | 15 | 50 | 19 |

| I6010 | 25 | 15 | 23 | 60 | 11.3 |

| I6015 | 38 | 15 | 23 | 60 | 16 |

| Tsawon lokaci | Samfuri | 250 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 10000 | 15000 |

| 610 | T1810 | 0.14 | 0.79 | 1.57 | 3.15 | 4.72 | 6.28 | 7.85 | - | - |

| I4010 | 0.20 | 0.43 | 0.84 | 1.68 | 2.50 | 3.40 | 4.22 | 7.90 | 12.60 | |

| I5015 | 0.08 | 0.18 | 0.40 | 0.75 | 1.20 | 1.50 | 1.85 | 3.71 | 5.56 | |

| I6015 | 0.13 | 0.23 | 0.48 | 0.71 | 1.40 | 1.90 | 2.31 | 4.65 | 6.96 | |

| T3320 | 0.05 | 0.10 | 0.20 | 0.41 | 0.61 | 0.81 | 1.05 | 2.03 | 3.05 | |

| T5020 | 0.08 | 0.15 | 0.28 | 0.53 | 0.82 | 1.10 | 1.38 | 2.72 | 4.10 | |

| 910 | T1810 | 1.83 | 3.68 | 7.32 | 14.63 | - | - | - | - | - |

| I4010 | 0.96 | 1.93 | 3.90 | 7.78 | 11.70 | - | - | - | - | |

| I5015 | 0.43 | 0.90 | 1.78 | 3.56 | 5.30 | 7.10 | 8.86 | - | - | |

| I6015 | 0.56 | 1.12 | 2.25 | 4.42 | 6.60 | 8.89 | 11.20 | - | - | |

| T3320 | 0.25 | 0.51 | 1.02 | 2.03 | 3.05 | 4.10 | 4.95 | 9.92 | - | |

| T5020 | 0.33 | 0.66 | 1.32 | 2.65 | 3.96 | 5.28 | 6.60 | - | - | |

| 1220 | T1810 | 5.46 | 10.92 | - | - | - | - | - | - | - |

| I4010 | 2.97 | 5.97 | 11.94 | - | - | - | - | - | - | |

| I5015 | 1.35 | 2.72 | 5.41 | 11.10 | - | - | - | - | - | |

| I6015 | 1.68 | 3.50 | 6.76 | 13.52 | - | - | - | - | - | |

| T3320 | 0.76 | 1.52 | 3.05 | 6.10 | 9.05 | - | - | - | - | |

| T5020 | 1.02 | 2.01 | 4.03 | 8.06 | - | - | - | - | - | |

| 1520 | T3320 | 1.78 | 3.56 | 7.12 | - | - | - | - | - | - |

| T5020 | 2.40 | 4.78 | 9.55 | - | - | - | - | - | - |

Filayen Aikace-aikace

Masana'antar Man Fetur: A wannan fanni, dole ne a yi amfani da gratings wajen jure tsatsa daga sinadarai daban-daban (acids, alkalis, solvents) yayin da ake cika ƙa'idodin tsaron wuta. Fiber na Vinyl Chloride (VCF) da Phenolic (PIN) su ne zaɓuɓɓuka mafi kyau saboda juriyarsu ta musamman ga tsatsa da kuma yawan jinkirin harshen wuta.

Wutar Lantarki ta Iska ta Gaɓar Teku: Feshin gishiri da kuma yawan danshi a muhallin ruwa suna da matuƙar lalata. Babban juriyar tsatsa da grating ɗin da aka yi da vinyl-chloride (VCF) yana ba shi damar jure zaizayar ruwan teku, yana tabbatar da tsaron tsarin da kuma tsawon rayuwar dandamalin teku.

Sufurin Jirgin Kasa: Wuraren jigilar jiragen ƙasa suna buƙatar kayan aiki masu dorewa, ƙarfin ɗaukar kaya, da juriyar wuta. Grating ya dace da dandamalin gyara da murfin hanyoyin magudanar ruwa, inda ƙarfinsa mai ƙarfi da juriyar tsatsa ke jure amfani akai-akai da muhalli mai rikitarwa.