Ingancin mold ɗin FRP yana da alaƙa kai tsaye da aikin samfurin, musamman dangane da saurin nakasa, juriya, da sauransu, wanda dole ne a fara buƙata. Idan ba ku san yadda ake gano ingancin mold ɗin ba, to don Allah a karanta wasu shawarwari a cikin wannan labarin.

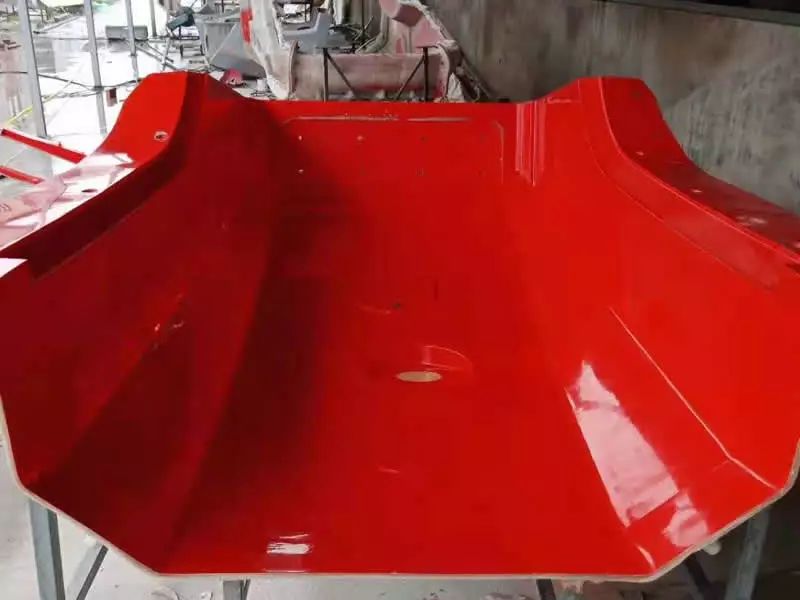

1. Ana duba saman mold ɗin lokacin da ya iso, kuma ana buƙatar kada a sami wani zane da ake gani a saman;

2. Kauri na murfin gel ɗin mold ya fi ko kuma daidai yake da 0.8mm, kuma kauri na murfin gel ɗin shine kauri na layin gel ɗin bayan an goge shi da kuma yin gyare-gyare, ba kauri na fim ɗin da aka jika ba;

3. Bai kamata a sami wani abu mai ɗauke da sinadarin resin a saman kusurwar mold ɗin ba.

4. Babban jikin mold ɗin, wato, zafin yanayin zafi na laminate FRP, bisa ga ma'aunin resin 2001 ≥110℃.

5. Ana buƙatar sheƙi da kuma siffa ta saman gashin gel ɗin don isa saman matakin A. Ga saman kwance, ana iya nuna siffa a sarari ba tare da nakasa ba.

6. Bukatun taurin saman gashi na gel: matsakaicin ƙimar taurin bas na maki 10 da aka auna ta hanyar jikin mold ya fi 35.

7. Yanayin saman mold ɗin ba ya buƙatar kumfa a saman mold ɗin, babu fiye da kumfa 3 a cikin 1m2 na kumfa da ake gani a cikin gel coat da mold laminate; babu alamun goga, ƙagagge da alamun gyara a saman mold ɗin, kuma babu fiye da ramuka 5 a cikin 1m2 na saman. A, babu wani abin da zai iya faruwa a layi.

8. Tsarin ƙarfe na mold ɗin ya dace, kuma dole ne ya kasance yana da tsarin firam gabaɗaya. Dole ne dandamalin mannewa ya kasance mai ƙarfi kuma ba ya lalacewa cikin sauƙi; na'urar hydraulic tana buɗewa kuma tana rufewa cikin sauƙi da santsi, ana iya daidaita saurin, kuma an samar da makullin tafiya, wanda zai iya cika lokutan buɗewa da rufewa sama da sau 1000 a amfani na yau da kullun.

9. An tsara mold ɗin bisa ga tsarin injin tsabtace kayan, ana buƙatar kauri na babban jiki don ya kai 15mm, kuma ana buƙatar kauri na flange na mold ɗin ya zama ≥18mm.

10. Maƙallan da aka sanya na mold ɗin fil ne na ƙarfe, kuma ya kamata a rufe fil ɗin da sassan FRP.

11. Ana duba layin yankewar mold ɗin sosai bisa ga ƙa'idar samfurin.

12. Girman da ya dace da mold ɗin ya kamata ya zama daidai, kuma kuskuren da ya dace tsakanin sassan da suka dace ya kamata ya zama ≤1.5mm.

13. Tsawon lokacin sabis na yau da kullun na mold bai kamata ya zama ƙasa da saitin samfura 500 ba.

14. Faɗin mold ɗin shine ±0.5mm a kowace mita mai layi, kuma bai kamata a sami rashin daidaito ba.

15. Duk girman mold ɗin an tabbatar da cewa yana da kuskuren ±1mm, kuma babu burr a saman laminate ɗin.

16. Ba a yarda saman mold ɗin ya sami lahani kamar ramukan filaye, tsarin bawon lemu, ƙyanƙyashewar takarda, fashewar ƙafar kaza, da sauransu ba, kuma baka ya kamata ya kasance mai santsi.

17. Ana shafa mold ɗin bayan an warke a zafin jiki mai zafi na 80°C, sannan a narkar da shi bayan awanni 8.

18. Ba za a iya canza siffar mold ɗin a ƙarƙashin yanayin zafi na waje na 90℃-120℃ ba, kuma saman ba zai iya bayyana alamun raguwa, tsagewa, da rashin daidaito ba.

19. Ya kamata a sami tazara fiye da 10mm tsakanin firam ɗin ƙarfe da mold ɗin, kuma haɗin jikin biyu ya kamata a lulluɓe shi da allon kwano ko allon layuka masu kauri iri ɗaya.

20. Haɗin da ke tsakanin mold ɗin da aka raba ba zai iya gushewa ba, ƙirar wurin da mold ɗin ta kasance mai dacewa, mold ɗin ya fito, aikin samfurin yana da sauƙi, kuma mold ɗin yana da sauƙin sakin sa.

21. Matsin lamba mara kyau na gaba ɗaya na mold yana ƙarƙashin 0.1, kuma ana kiyaye matsin lamba na tsawon mintuna 5.

Lokacin Saƙo: Maris-22-2022