Ingancin gyare-gyaren FRP yana da alaƙa kai tsaye da aikin samfurin, musamman dangane da ƙimar lalacewa, karko, da sauransu, waɗanda dole ne a fara buƙata.Idan baku san yadda ake gano ingancin mold ba, don Allah karanta wasu shawarwari a cikin wannan labarin.

1. Ana gudanar da duban gyare-gyaren da aka yi a lokacin da ya zo, kuma ana buƙatar cewa babu wani zane mai gani a saman;

2. Girman gashin gashi na mold ya fi girma ko daidai da 0.8mm, kuma kauri na gel ɗin gel shine kauri na gel ɗin gel ɗin bayan warkewa da gyare-gyare, ba nauyin fim ɗin rigar ba;

3. Kada a kasance a yi ajiyar guduro a saman kusurwar mold.

4. Babban jiki na mold, wato, thermal nakasawa zafin jiki na FRP laminate, bisa ga 2001 guduro siga ≥110 ℃.

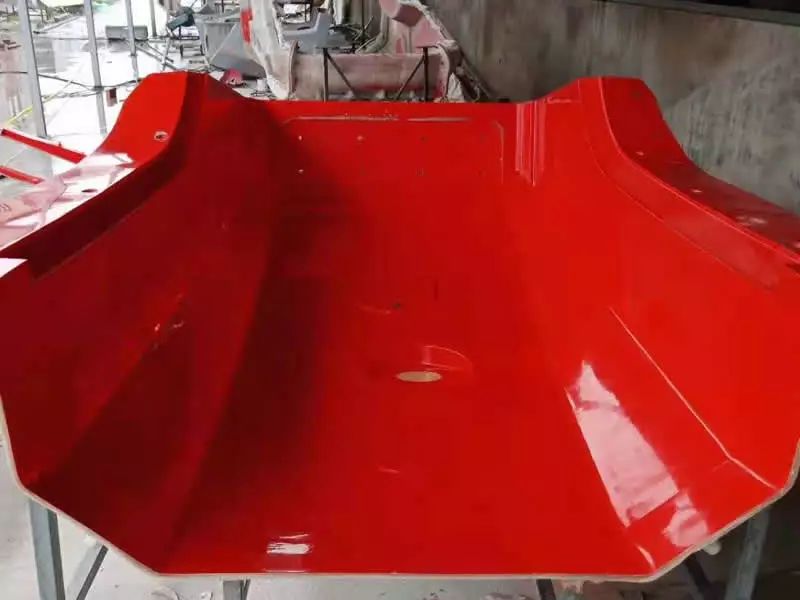

5. Ana buƙatar mai sheki da lebur na saman gashin gel ɗin don isa matakin A-matakin.Don jirgin sama na kwance, ana iya nuna silhouette a fili ba tare da nakasawa ba.

6. Abubuwan buƙatun tauri na saman gashin gel: matsakaicin ƙimar taurin bas na maki watsawa 10 da aka auna ta jikin mold ya fi 35.

7. Yanayin yanayin da ake bukata ba buƙatar kumfa a kan farfajiyar ƙirar ba, ba fiye da 3 kumfa a cikin 1m2 na kumfa mai bayyane a cikin gel gashi da laminate mold;babu alamun buroshi na zahiri, tarkace da alamun gyarawa a saman fasinja, kuma babu fiye da filaye 5 a cikin 1m2 na saman.A, ba za a iya samun abin al'ajabi ba.

8. Ƙarfin ƙarfe na ƙirar yana da ma'ana, kuma dole ne ya sami tsarin tsarin gaba ɗaya.Dandalin matsawa dole ne ya kasance mai ƙarfi kuma ba zai zama nakasa ba cikin sauƙi;na'urar hydraulic tana buɗewa da rufewa a hankali kuma a hankali, saurin yana daidaitawa, kuma ana ba da canjin tafiya, wanda zai iya saduwa da lokacin buɗewa da rufewa> sau 1000 a cikin amfani na yau da kullun.

9. An tsara samfurin bisa ga tsarin samfurin samfurin, ana buƙatar kauri na babban jiki don isa 15mm, kuma ana buƙatar kauri na flange na mold ya zama ≥18mm.

10. A saka fil na mold ne karfe fil, kuma fil da FRP sassa ya kamata a shãfe haske.

11. Ana bincika layin yankan na mold daidai da ƙayyadaddun samfurin.

12. Girman ma'auni na mold yana buƙatar zama daidai, kuma kuskuren daidaitawa tsakanin sassa masu dacewa ya kamata ya zama ≤1.5mm.

13. Rayuwar sabis na yau da kullun na mold kada ta kasance ƙasa da samfuran samfuran 500.

14. Ƙaƙwalwar ƙira shine ± 0.5mm a kowace mita mai layi, kuma kada a sami rashin daidaituwa.

15. Dukkanin nau'i na mold an tabbatar da samun kuskuren ± 1mm, kuma babu burr a saman laminate.

16. Ba a yarda da saman mold don samun lahani irin su pinholes, nau'in kwasfa na orange, zane-zane na sandpaper, fashewar ƙafar ƙafar kaji, da dai sauransu, kuma baka ya kamata ya zama m canji.

17. Ana warkewar ƙwayar cuta a babban zafin jiki na 80 ° C, kuma an rushe bayan sa'o'i 8.

18. A mold ba za a iya maras kyau a karkashin exothermic ganiya yanayin 90 ℃-120 ℃, da kuma surface ba zai iya bayyana shrinkage alamomi, fasa, da rashin daidaito.

19. Ya kamata a sami tazara fiye da 10mm tsakanin firam ɗin ƙarfe da ƙirar, kuma haɗin haɗin jikin biyu ya kamata a sanya shi da katako ko allunan Layer Layer na kauri ɗaya.

20. Ba za a iya kawar da haɗin gwiwa na gyare-gyaren gyare-gyare ba, ƙirar ƙirar ƙirar ƙira ta dace, an saki ƙirar, aikin samfurin yana da sauƙi, kuma ƙirar yana da sauƙin saki.

21. Gaba ɗaya mummunan matsa lamba na mold yana ƙarƙashin 0.1, kuma ana kiyaye matsa lamba don minti 5.

Lokacin aikawa: Maris 22-2022