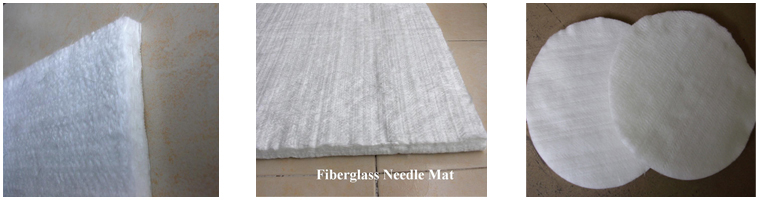

1. Jikin allura

Jigon allura ana raba shi zuwa yankakken allurar zare da kuma jigon allurar zare mai ci gaba. Jigon allurar zare da aka yanka ana yanka shi ne a yanka zaren gilashin da ke tafiya zuwa 50mm, a saka shi a kan abin da aka sanya a kan bel ɗin jigilar kaya a gaba, sannan a yi amfani da allurar sandar don huda allura, kuma allurar za ta huda zaren da aka yanka a cikin abin da aka sanya. Ƙoƙarin ƙugiya yana kawo wasu zaren don samar da tsari mai girma uku. Tsarin da aka yi amfani da shi na iya zama siririn yadi na zaren gilashi ko wasu zaren, kuma wannan jigon allura yana da laushi. Babban amfaninsa sun haɗa da kayan kariya na zafi da kayan kariya na sauti, kayan rufin zafi, kayan tacewa, kuma ana iya amfani da shi wajen samar da FRP, amma ƙarfin FRP yana da ƙasa kuma iyakokin amfani yana da iyaka. Wani nau'in jigon allurar zare mai ci gaba shine jigon da ake jefa zaren gilashi mai ci gaba bazuwar a kan bel ɗin raga mai ci gaba tare da na'urar jefa waya, sannan a yi allura ta cikin farantin allura don samar da tsari mai girma uku wanda zaren ke haɗuwa. Ana amfani da wannan nau'in jigon galibi wajen samar da zaren da za a iya amfani da shi a matsayin mai ƙarfi na zaren gilashi.

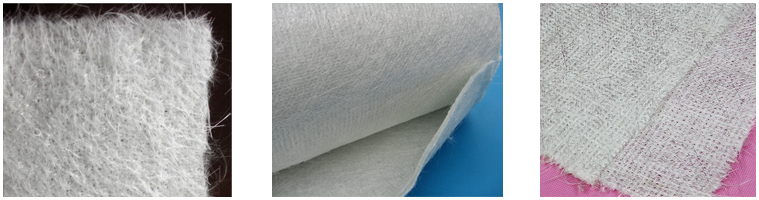

2. Tabarmar Zaren Fiberglass da Aka Yanka - Maƙallin Foda

Ana sanya zare-zaren da aka yi da gilashi a lokacin aikin zane ko kuma zare-zaren da aka yi da bututun zare-zaren da aka cire daga bututun zaren da aka yi da shi a kan bel mai motsi mai ci gaba a cikin hoto na 8 kuma ana haɗa shi da manne foda. Zaren da ke cikin tabarmar zaren gilashi mai ci gaba yana ci gaba, don haka yana da tasirin ƙarfafawa mafi kyau akan kayan haɗin.

3.Gilashin fiberglassTabarmar zare da aka yanke - Maƙallin emulsion

A yanke zare na gilashi (wani lokacin kuma a yi amfani da roving mara jujjuyawa) zuwa tsawon mm 50, a shimfiɗa shi ba zato ba tsammani amma daidai a kan bel ɗin raga, sannan a shafa manne mai kauri ko yayyafa foda don dumama da ƙarfafawa da ɗaure shi cikin gajeriyar jifa ta siliki da aka yanke. Ana amfani da tabarmar zare da aka yanke galibi a cikin shimfida hannu, yin allo akai-akai da gyaran matsi da kuma tsarin SMC. Bukatun inganci don tabarmar zare da aka yanka sune kamar haka: ① Ingancin yanki iri ɗaya ne a kan faɗin alkibla; ② Zaren da aka yanka suna rarraba daidai a saman tabarmar ba tare da manyan ramuka ba, kuma an rarraba manne daidai; ③Yana da matsakaicin ƙarfin tabarmar busasshiya; ④Madalla Shigar da resin da kuma iyawa.

Lokacin Saƙo: Agusta-12-2021