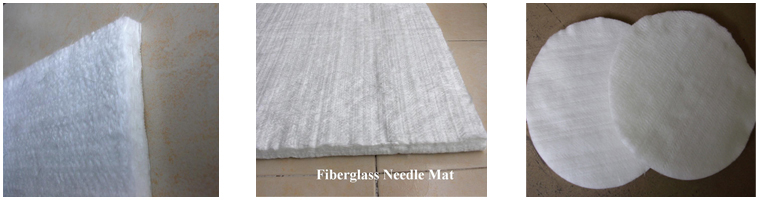

1. Allura ji

An raba jiƙan allura zuwa yankakken allurar fiber ji da kuma ci gaba da jin allurar igiya.Yankakken zaren da ake buƙata ji shine a datse fiber ɗin gilashin da ke motsawa cikin 50mm, ba da gangan a ajiye shi a kan abin da aka ɗora a kan bel ɗin jigilar kaya a gaba, sannan a yi amfani da allura mai shinge don naushin allura, kuma allurar za ta huda yankakken fiber a cikin substrate. ƙugiya mai ɗamara tana kawo wasu zaruruwa don samar da tsari mai girma uku.Abun da aka yi amfani da shi na iya zama masana'anta na bakin ciki na fiber gilashi ko wasu zaruruwa, kuma wannan jigon da ake buƙata yana da ɗanɗano.Babban amfaninsa sun haɗa da abubuwan da ake amfani da su na zafi da kuma kayan daɗaɗɗen sauti, kayan rufin zafi, kayan tacewa, kuma ana iya amfani da su wajen samar da FRP, amma ƙarfin FRP yana da ƙasa kuma ikon amfani yana da iyaka.Wani nau'in allura mai ci gaba da jin daɗi shine ji wanda ci gaba da igiyoyin gilashi ke jefa bazuwar a kan bel ɗin raga mai ci gaba tare da na'urar jefa waya, sannan a yi masa allura ta farantin allura don samar da tsari mai nau'i uku wanda fibers ke haɗuwa.Ana amfani da irin wannan nau'in ji a cikin samar da fiber gilashin ƙarfafa zanen gadon filafili.

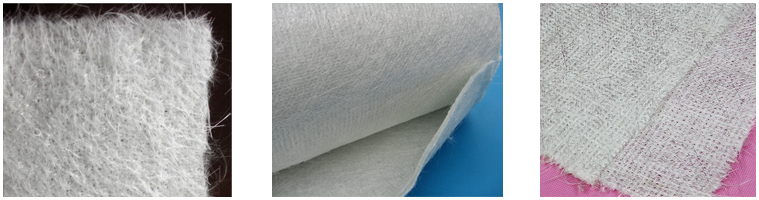

2. Fiberglass Yankakken Strand Mat - Foda mai ɗaure

Gilashin danyen filaments da aka kafa yayin aikin zane ko ci gaba da ƙwaƙƙwaran filament ɗin da aka yi ritaya daga bututun filament ɗin da aka ɗora a kan bel ɗin raga mai ci gaba da motsi a cikin adadi na 8 kuma an haɗa su da mannen foda.Fiber a cikin gilashin gilashin fiber mai ci gaba yana ci gaba da ci gaba, don haka yana da tasiri mai kyau na ƙarfafawa akan kayan haɗin gwiwa.

3.FiberglasYanke tabarma - Emulsion mai ɗaure

Yanke fiber gilashin (wani lokacin kuma amfani da roving untwisted) zuwa tsawon 50mm, yada shi ba da gangan ba amma a ko'ina a kan bel ɗin raga, sannan a shafa emulsion m ko yayyafa foda dauri wakili don zafi da ƙarfi da kuma haɗa shi a cikin gajeren Yanke danyen siliki ji.Ana amfani da tabarmi da aka yanka a cikin shimfiɗar hannu, ci gaba da yin allo da gyare-gyaren gyare-gyare da tsarin SMC.Abubuwan da ake buƙata don yankakken matsi na igiya sune kamar haka: ① Matsayin yanki shine uniform tare da shugabanci mai faɗi;② Ana rarraba sassan yankakken a ko'ina a cikin shimfidar tabarmar ba tare da manyan ramuka ba, kuma an rarraba mai ɗaure daidai;③Yana da matsakaicin bushewar tabarma;④ Excellent The resin infiltration da permeability.

Lokacin aikawa: Agusta-12-2021